Benefits of Bucket Elevators

Bucket Elevator, is a piece of necessary useful machinery, as it is capable to convey light to heavy supplies. Bucket Elevator or Bucket Conveyor consists of the number of buckets attached for loading and transmitting the material with a strong belt to move on. It is a necessary machine, which is best suited to the oil mills, food industries, grain industries, cattle field industries, fertilizer industries, pet coke handling, and various chemical industries, etc.

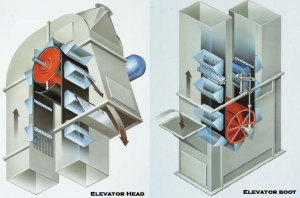

Neo Bucket Elevators is a system for elevating bulk materials. Nowadays, continuous developments in bucket shape, head and boot profiles, manufacturing, and operating specifications are being done. Unique bucket shapes and the chains or belts as traction elements and various combinations make an efficient bucket elevator.

Types of Bucket Elevators

Bucket Elevators are serving both the inclined and vertical movement of material with ease. The most popular is a centrifugal discharge elevator, which may well be vertical or inclined. Unlike earlier elevators, small, flat steel buckets, these days modern elevators use a rubber belt with plastic buckets, which has made them a lot more efficient and durable.

Inclined Elevators, have the buckets set close together may have the discharge chute set partly beneath the head pulley. The speed of the inclined elevator is low mainly because it doesn’t rely on the centrifugal force.

Vertical Elevators, on the other hand, have spaced buckets with rounded bottoms. The supplies from a boot, a pit, or a pile might be readily loaded to a centrifugal elevator. The shape of buckets is triangular and close to on the belt with small or no space in between them. This kind of elevator is becoming employed to carry heavy material and lift at a slow pace.

The principal function of an elevator is to continue pulsating flow of material through vertical handling. Apart from centrifugal discharge type, continuous variety and super capacity elevators are there to serve. Slow Elevators may be applied in case of lumpy and abrasive materials. Apart from conventional bucket elevators, shelf elevators, cradle elevators, and a kind of overlapping bucket elevators, etc. are in use.