Bucket elevators manufacturers

The Bucket Elevator, as its name suggest, it is an arrangement of buckets to elevate material vertically. Nowadays, the bucket elevator is in great use, its main task is to handle bulk material and elevate vertically, irrespective of whether the material to be elevated is a free flow of material with poor flow liquid consistency.

Installation of bucket elevator

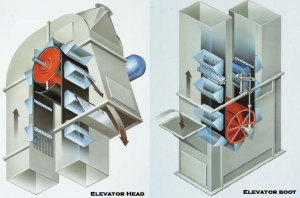

The bucket elevator requires a flat surface to be mounted on solid concrete, The foundation should be horizontal, secure enough to give support to the installed bucket elevator in order to achieve vertical requirements. The Middle and upper casing section of a higher height bucket elevator should be connected and supported well with the neighboring building or any solid structure to give it stability. . The bucket elevators are going through continuous development, regarding shapes and sizes of buckets, head and boot profiles, manufacturing and operating specifications of the machine.

The Bucket Elevator is successfully elevating, whether it may be the most free-flowing material or material with poor flow characteristics. The rate at which, material be elevated depends on various factors, in addition to the obvious effects of bucket design, capacity, and speed.

Number one bucket elevator manufacturers in NCR

Neo conveyors are into designing, manufacturing bucket elevators to handle bulk material without material deterioration, undisturbed until it is discharged.