How to select bucket elevator

- Type of material- bulk, heavy, free flow, etc.

- Type of product – raw material or finished product, Fragile or hard, Liquid, semi-solids, etc.

- Direction – to be moved in vertical, horizontal + vertical + horizontal ( Z Type) direction

- Speed – Variable or fixed

- Height – Level of Inclination

- Weight – heavy or light, liquid or semi-solid, grains, sand, concrete, etc.

- Distance – to be maintained between the products.

- Type of industry

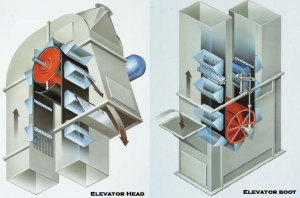

- Pulley – a requirement of pulleys for transportation

- Size – Specific size of buckets to avoid overloading