Benefits of bucket elevator

In today’s world, the latest technologies are applied in all walks of life, and this goes with the usage of bucket conveyors, also. They are the number of buckets connected with each other onto a belt.

They are chain driven as well as Belt driven. They are available in different sizes, shapes, and types, as per the material required to be moved, vertically. They are more popular in oil mills, mining industries, construction areas, etc. Its simplicity has made it, really popular, in various industries, specifically in bulk material handling and processing applications.

Advantages of bucket elevator

- The Bucket elevators are serving effectively, to move both heavy and light material with ease and accuracy. The Bucket Elevators are successfully elevating, the most free-flowing material, as well as material with poor flow characteristics, flowing bulk solids or powders, etc. The process of raising and lowering of material is done with the help of mechanical and hydraulic power.

- The buckets conveyor’s benefits to deal with any type of material, strong elevation, durability less power consumption, easy transportation, lifting even in the highest location, capacity, smooth and steady functioning, etc. have proved it beneficial.

- The bucket elevators are trusted machines, which are economical, serve for a long period of time, reduce labor cost, no interruption in transportation, all these have made it popular and beneficial.

Types of bucket elevator

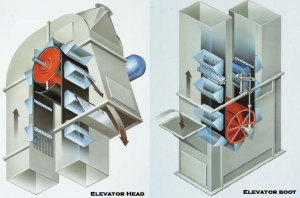

- Centrifugal discharge bucket elevator – The Centrifugal Discharge elevator uses profound buckets moving at a generally fast, permitting centrifugal power to move the material out of the bucket and into the discharge opening. It is particularly appropriate for tough and grating materials that can withstand scooping out of the boot and throwing out of the discharge.

- Continuous discharge bucket elevator – Z type bucket elevators are designed to handle products without material deterioration, the product moves undisturbed until it is discharged.

Keeping in mind, Neo Conveyors, are designing, such Bucket Conveyor, by giving proper shape and specific design to it. Buckets are accordingly, attached with the required capacity and the speed is maintained to elevate it.

Please refer to our other topics

-

Benefits of Bucket Elevators for bulk materials handling

-

Different Ways of material discharging by Bucket Elevator