Neo Conveyors manufacturer bucket elevators with belt type, ring chain type, and plate chain type which is mainly suitable for handling feed mills, flour mills, rice mills, oil, starch factory, grain depot, port terminals, and other bulk materials.

Types of bucket elevators discharge

Different discharge methods of bucket elevators are centrifugal discharge bucket elevator, gravity type bucket elevator, and hybrid type bucket elevator. Details as below:

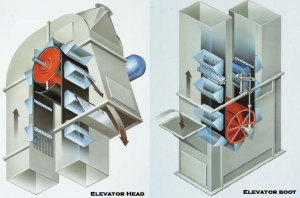

Types of bucket elevator

- Centrifugal discharge elevator: Materials are discharged by using centrifugal force to throw the material away from the discharging outlet. It is suitable for dry with fast lifting speed and small particles.

- Gravity Type: Materials are discharged by and suitable for material that is large and fragile.

- Hybrid type: Materials are discharged by using centrifugal force and gravity force, which is suitable for material with poor fluidity and big humidity.

Bucket elevator manufacturer

Neo Conveyors are professional manufacturers of Belt conveyors, Vibrating screens, Bucket elevators, Screw conveyors, Scraper conveyors using the world’s most advanced technology. We manufacturer as per customer requirements. Please contact us without any hesitation.